CHARACTERISTICS

– Choose from a multitude of deicing material discharge configurations – rear discharge, front discharge or front left and/or right side discharge utilizing a cross conveyor

– Spreader attached to chassis through Aeon rubber helper springs to reduce shock and vibration.

– Top screens and access ladder are standard components.

– 24” wide main conveyor D88K chain rated @ 49,000 lbs

– 7.7 cu in main conveyor hydraulic motor

– Lowest center of gravity in spreader industry

– Significant weight savings as compared to competitive versions of 12 cu yd spreaders.

– Various types of ladders, grab handles, lighting systems (including MTQ/QMT version).

– Automated spreader controllers.

– Pre-wet system including two (2) 300 litres (80 US gallons) liquid tanks.

– Multiple lights options

– Plastic fender & LED lights

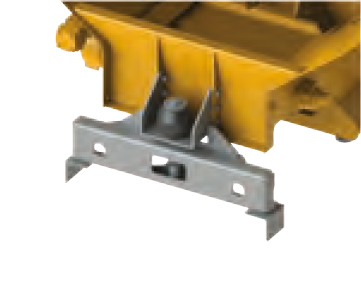

12 urethane discs between spreader and chassis frame reduces vibration.

The unique Triflex three points mounting system.

With rear tailgate and front lift hoist for dumping capabilities

– Hopper is provided with tailgate to enable removal of load upon completion of material spreading.

– Utilizes existing front lift telescopic hoist on truck to attach to spreader.

– Fully welded steel construction.

– Spreader also available in 304 stainless steel.

– Rear or front center discharge configurations.

– Quick cycle time to remove dump body from chassis and replace with this particular type of hopper spreader.

Quick cycle time to remove dump body from chassis and replace with this particular type of hopper spreader.

| MODELS NUMBER |

WATER LEVER CAPACITY |

HOPPER LENGTH |

HOPPER WIDTH |

HAUTEUR DES CÔTÉS |

OVERALL LENGTH |

OVERALL HEIGHT |

OVERALL WIDTH WITH LAD |

WEIGHT APPROX. |

CAPACITY |

|---|---|---|---|---|---|---|---|---|---|

| TCD-10-56-XE | 5.6’ cu yds | 10’ | 92’’ | 56’’ * | 10’ | 77’’ | 102’’ | 3 695 lbs | 6.8 cu yds |

| TCD-10-56-XD | 6.1’ cu yds | 10’ | 92’’ | 56’’ * | 10’ | 77’’ | 102’’ | 4 215 lbs | 6.8 cu yds |

| TCD-12-56-XE | 7.0’ cu yds | 12’ | 92’’ | 56’’ * | 12’ | 77’’ | 102’’ | 4 335 lbs | 8.4 cu yds |

| TCD-12-56-XD | 7.4’ cu yds | 12’ | 92’’ | 56’’ * | 12’ | 77’’ | 102’’ | 4 815 lbs | 8.4 cu yds |

| TCD-14-63-XE | 10.6’ cu yds | 14’ | 92’’ | 63’’ * | 14’ | 79’’ | 102’’ | 4 830 lbs | 12.3 cu yds |

| TCD-14-63-XD | 11.1’ cu yds | 14’ | 92’’ | 63’’ * | 14’ | 79’’ | 102’’ | 5 400 lbs | 12.3 cu yds |

| TCD-16-63-XE | 12.3’ cu yds | 16’ | 92’’ | 63’’ * | 16’ | 79’’ | 102’’ | 5 265 lbs | 14.2 cu yds |

| TCD-16-63-XD | 12.8’ cu yds | 16’ | 92’’ | 63’’ * | 16’ | 79’’ | 102’’ | 5 800 lbs | 14.2 cu yds |

*Height of spreaders includes screens | Weight of Slide-in Spreaders includes chute and V-box