| UH3000 | UH4000 | UH5000 | ||

|---|---|---|---|---|

| Hopper capacity | m3 | 4 to 7 | 5 t0 12 | 6.5 to 16 |

| cu yd | 5.2 to 9.2 | 6.5 to 15.7 | 8.5 to 21 | |

| Brine tank capacity | l | 2270 | 2600 to 3000 | 3700 |

| gal | 600 | 690 to 790 | 980 | |

| Min/max. spreading width |

m | 2÷12 | 2÷12 | 2÷12 |

| yd | 2.2÷13.1 | 2.2÷13.1 | 2.2÷13.1 | |

| Min/max. salt dispensing capacity |

g/m2 | 5÷40 | 5÷40 | 5÷40 |

| oz/sq yd | 0.21÷1.7 | 0.21÷1.7 | 0.21÷1.7 | |

| Min/max. grit dispensing capacity |

g/m2 | 20÷350 | 20÷350 | 20÷350 |

| oz/sq yd | 0.85÷14.8 | 0.85÷14.8 | 0.85÷14.8 | |

| Hopper lenght | mm | 3400 | 4200 | 5200 |

| ft | 11.15 | 13.78 | 17.06 | |

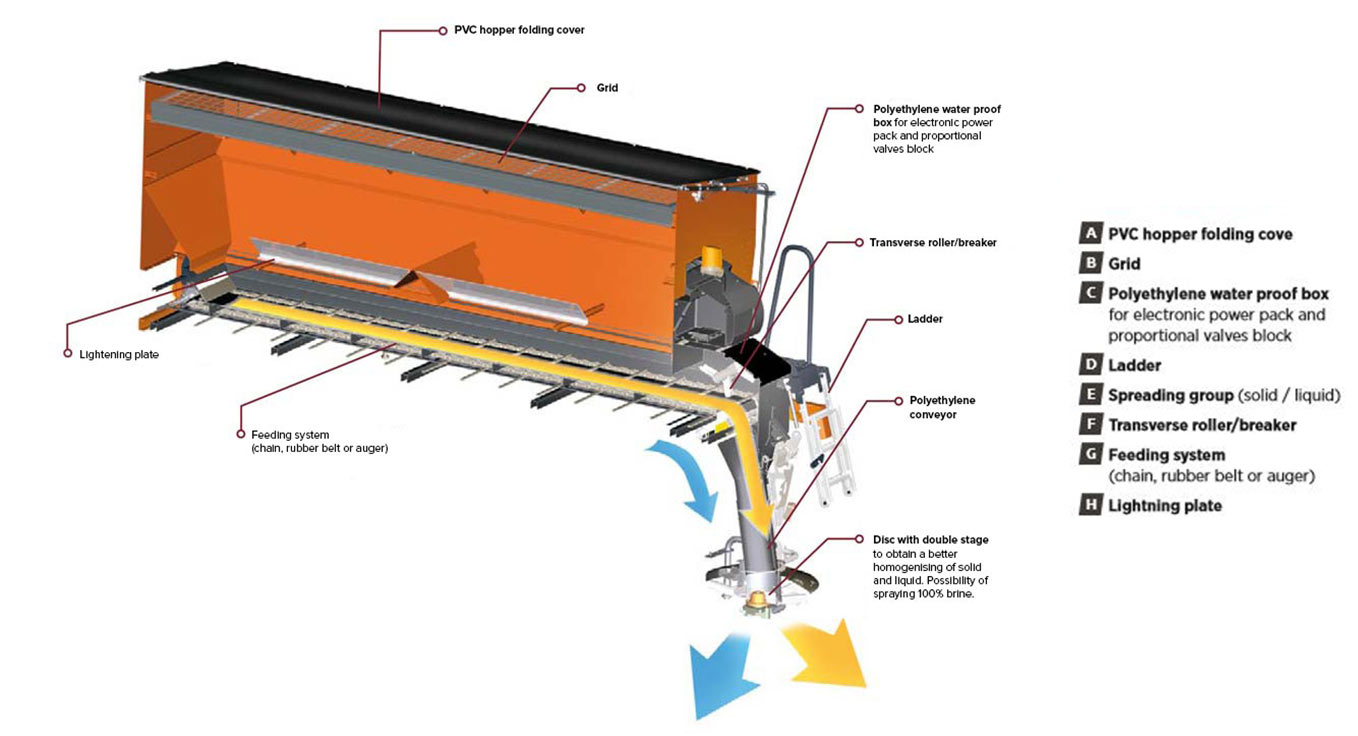

FEEDING SYSTEMS

UH – Chain

The feeding system is realized by a wide steel chain conveyor with cross-bars. The chain is guided by toothed pinions that enables a constant traction maintaining a correct translation synchrony, without skidding

UK – RUBBER BELT

The feeding system is realized by a double layer natural rubber belt with polyester and nylon core. The traction roller that moves the rubber belt is crowned to avoid side deviations and tired to minimize skidding.

UP – AUGER

The feeding system is realized by an auger with variable pitch turn that is designed to assure a continuous feeding of the material and a linear emptying of the hopper. The auger is finished with a special paint treatment to provide lasting protection against the corrosion.

ECOSAT

Latest generation microprocessor controlsystems, with maximum flexibility in programming and visualizing the different spreading parameters: width, asymmetry and dosage depending on the vehicle speed. Six different tools in all-in-one control box

ASYMMETRY

Electric regulation of spreading asymmetry in 5 pre-set positions from the driver’s cab

SECOND DISC

Second spreading disc to increase the salt and/or brine spreading width.

SPRAYER BAR

Spraying bar through pressure nozzles for the spraying of 100% of the brine.

LATTER

AISI 304 stainless steel ladder for easy accessibility positioned in the rear right part.

PVC HOPPER COVER

PVC hopper folding cover manually opened from the ground with steel structure.

GRID

Galvanized grid. Possibility of AISI 304 stainless steel grid (opt. G1/X).